Product Introduction

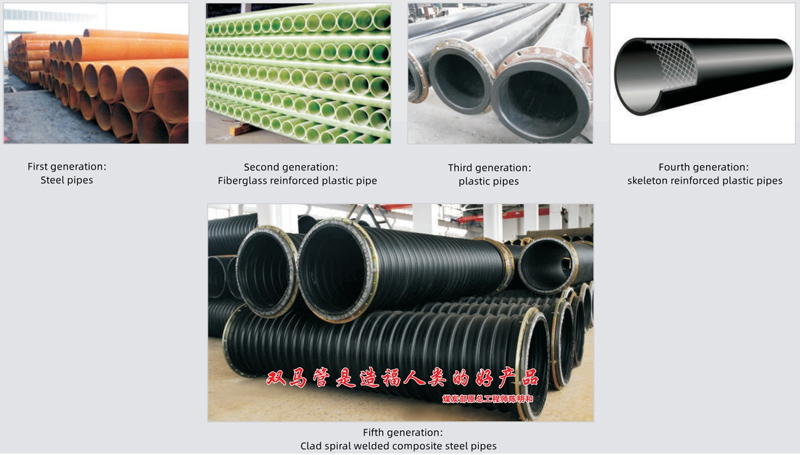

PE coated spiral welded composite steel pipe (referred to as PE coated spiral welded composite steel pipe) is a new type of gas drainage pipeline used in coal mines. In the coal mine gas drainage system, the pipeline section accounts for more than 80% of the entire system and is an important material for ensuring coal mine safety production. In traditional gas drainage pipes, there are some defects in seamless steel pipes, fiberglass pipes, plastic pipes, and skeleton reinforced plastic pipes, which affect the safety production of coal mines. The PE coated spiral welded composite steel pipe used for coal mine gas drainage belongs to the fifth generation product of gas pipelines. It inherits various excellent characteristics of traditional gas pipelines and makes up for the defects of existing gas pipelines (see Table 1 for relevant characteristics comparison). This new type of gas pipeline has obtained two national invention patent certificates (patent numbers ZL201010288533.6 and ZL200810228610.1), and has passed the certification of the National Mining Product Safety Mark Center.

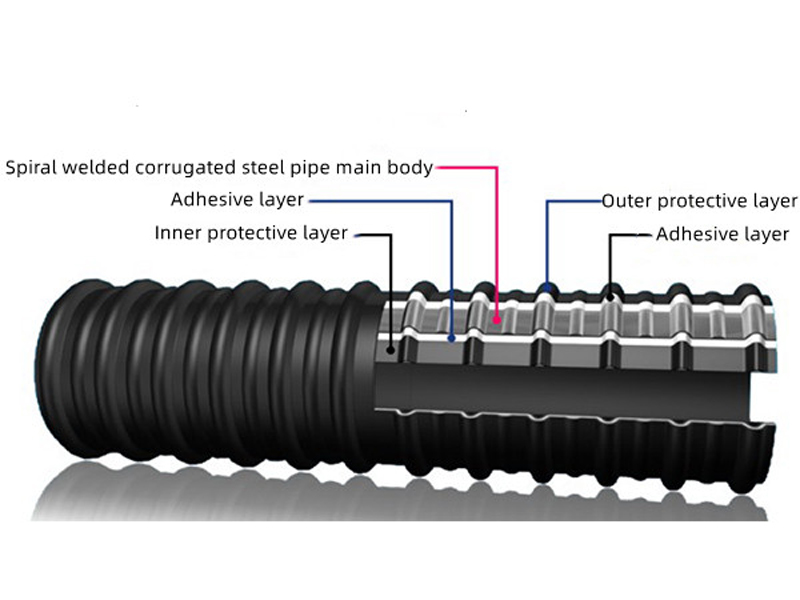

Spiral welded corrugated steel pipe main bodyAdhesive layerInner protective layerOuter protective layerAdhesive layer

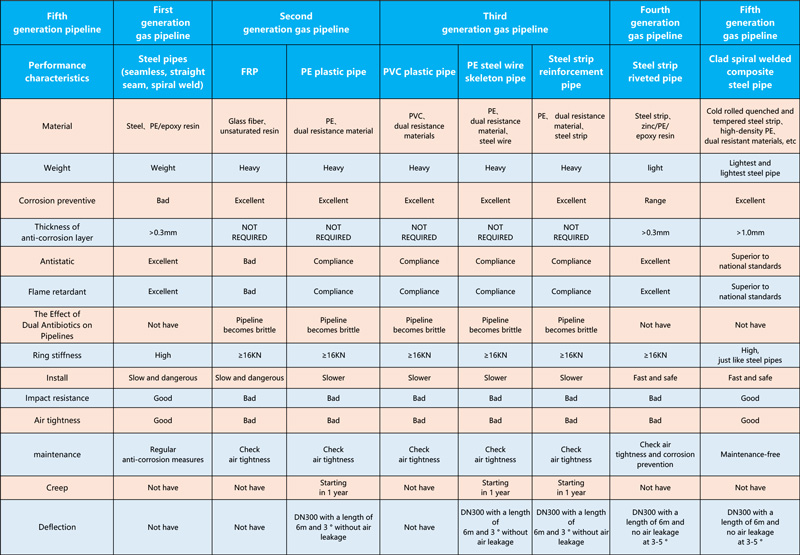

Comparison of Performance Characteristics of Five Generation Gas Pipelines

First generation: Steel pipesSecond generation: Fiberglass reinforced plastic pipeThird generation: plastic pipesFourth generation: skeleton reinforced plastic pipesFifth generation: Clad spiral welded composite steel pipesShuangma tube is a good product that benefits humanity

Fifth generation pipelineFirst generation gas pipelineSecond generation gas pipelineThird generation gas pipelineFourth generation gas pipelineFifth generation gas pipelinePerformance characteristicsmaterialweightcorrosion preventiveThickness of anti-corrosion layerantistaticFlame retardantThe Effect of Dual Antibiotics on PipelinesRing stiffnessinstallImpact resistanceAir tightnessmaintenancecreepdeflectionSteel pipes (seamless, straight seam, spiral weld)

FRPPE plastic pipePVC plastic pipePE steel wire skeleton pipeSteel strip reinforcement pipeSteel strip riveted pipeClad spiral welded composite steel pipeSteel、PE/epoxy resinGlass fiber、unsaturated resinPE、dual resistance materialPVC、dual resistance materialsPE、dual resistance material、steel wirePE、 dual resistance material、steel stripSteel strip、zinc/PE/epoxy resinCold rolled quenched and tempered steel strip、 high-density PE、 dual resistant materials, etcWeightBadNOT REQUIREDExcellentNot haveHighSlow and dangerousGoodRegular anti-corrosion measuresNot haveHeavyExcellentPipeline becomes brittleHigh, just like steel pipesSlow and dangerousBadCheck air tightnessStarting in 1 yearDN300 with a length of 6m and 3 ° without air leakage Lightest and lightest steel pipeSuperior to national standardsFast and safeMaintenance-freelightRangeComplianceSlowerCheck air tightness and corrosion preventionDN300 with a length of 6m and no air leakage at 3-5 °

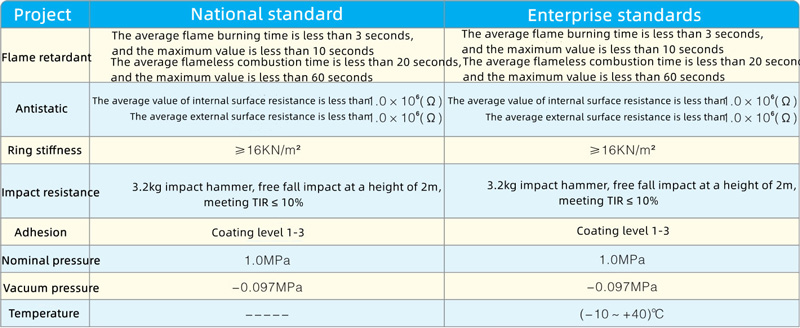

ProjectFlame retardantAntistaticRing stiffnessImpact resistanceAdhesionNominal pressureVacuum pressureTemperatureNational standardThe average flame burning time is less than 3 seconds, and the maximum value is less than 10 secondsThe average flameless combustion time is less than 20 seconds, and the maximum value is less than 60 secondsThe average value of internal surface resistance is less thanThe average external surface resistance is less than10^6(Ω)3.2kg impact hammer, free fall impact at a height of 2m, meeting TIR ≤ 10%Coating level 1-3 Enterprise standards

Technical performance of PE coated spiral welded composite steel pipes for gas drainage in coal mines

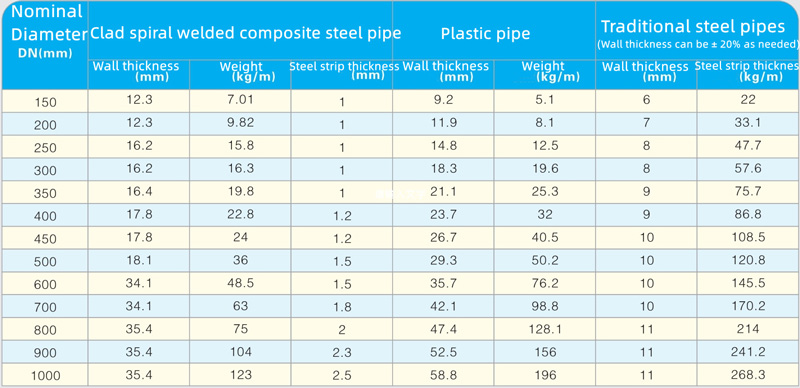

Comparison of weight between PE coated spiral welded composite steel pipes, plastic pipes, and traditional steel pipes for gas drainage in coal mines

Under the condition of nominal pressure of 1.0Mpa, compare the unit weight of PE coated spiral welded composite steel pipe, plastic pipe, and traditional steel pipe:

Nominal DiameterDN(mm)

Clad spiral welded composite steel pipePlastic pipeTraditional steel pipes(Wall thickness can be ± 20% as needed)

Wall thickness(mm)

Weight(kg/m)

Steel strip thickness(mm)

Nominal DiameterDN(mm) Average inner diameter(mm) Average outside diameter(mm) Rib height(mm) Tube weight(kg/m) Pan head neck thickness(mm) Steel strip thickness(mm)

Processing technology

Main process of pipeline

After rust removal, the cold-rolled quenched and tempered steel strip is pulled out with n-shaped reinforcing ribs through seven passes of pressing, wound into a tube, and welded into a spiral steel pipe using pulse MIG welding or welding process.

The function of n-shaped reinforcing ribs is to increase the stiffness of the pipe body ring by more than 6 times (for steel pipes of the same thickness).

MIG is an international cutting-edge welding process with 20 welding points per second, ensuring no false or missed welding, thereby ensuring the sealing of the pipe body.

Coating processing technology

While welding the main body of the pipeline, the inner and outer parts of the pipeline are coated with plastic by an extrusion machine, which not only ensures the bonding strength between the pipeline and the main body, but also ensures the flame retardant and anti-static performance of the pipeline.

Process of flange head

Install the fixed length pipeline into the casting plate machine mold, and after adding flanges, preheating, injection molding, insulation, and cooling, the process is completed and the mold can be released. The injection tray material is mainly made of high-strength PE, supplemented by other modified materials, which tightly combines the formed tray head with the pipeline spiral groove structure, while ensuring the structural strength and flame retardant and anti-static performance requirements of the cast tray head.